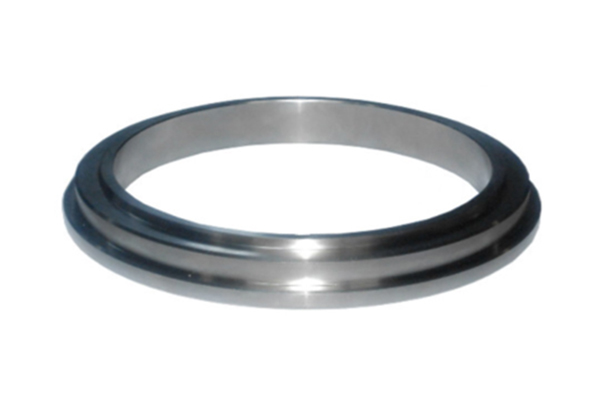

ʻOki apo Schwing

Hōʻike huahana

Ua kapa ʻia ke apo ʻokiʻoki ʻo ke apo ʻaʻahu, he ʻāpana nui ia o ke kaʻa kaʻa paila. Hoʻohālikelike ʻia me he torus. Ke hana nei ka mokuʻāina hana i ka neʻe ʻāhi, no laila ua kapa ʻia ke apo ʻoki.

I kēia manawa, ʻo nā mea hana maʻamau: (1) High chromium alloy cast iron. (2) Tungsten carbide. (3) ʻO ka carbide sima. (4) Alloy ceramics.

ʻO ka pā aniani, ke apo ʻokiʻoki, ka puna wai puna, ka ʻano huaʻano kūikawā, ka lima hoʻololi, ke sila, ka nui a me ka liʻiliʻi liʻiliʻi a me ka S-tube welded kino ka pahu S-tube.

ʻO ka pā aniani a me ke apo ʻokiʻoki e pāʻani nui i kēia mau hana:

ʻO ka hana hoʻopaʻa ʻana: Hana nui lākou me nā puna wai, a hoʻopaʻa ʻia ke āpau e ke kaomi ponoʻī a me nā puna wai, i loaʻa i ke apo ʻokiʻoki i kahi hopena hoʻopaʻa ponoʻī, a laila e hoʻonui ai i ke kaomi lawe ʻana o ka pahu S tube.

Ka hopena ho'ēmi kumukūʻai: Ma muli o ka hopena o ka pā aniani a me ke apo ʻokiʻoki, hoʻololi lākou i ka lole ma waena o ke awa hānai a me ka cylinder material, a pale i ke ola lawelawe o nā mea ʻelua.

ʻO kā lākou kumu hana ʻo ia: ma lalo o ka hana o ka ikaika pre-tightening o ka unfolding nut, ua hoʻopaʻa ʻia ka puna wai puna, a pili pono ke apo ʻoki i ka pā aniani. ʻO ke apo ʻokiʻoki a me ka pā aniani no ka hui hoʻoneʻe pili. Ma hope o ka ʻaʻahu ʻana, hiki i ka puna wai ke hilinaʻi i kona elasticity ponoʻī e hoʻopaʻi i ka ʻaʻahu o ka pā aniani a me ke apo ʻoki a hoʻopau i ke āpau o ka lole. Ke piʻi ka ʻaʻahu o ke apo ʻokiʻoki i kahi pae, ʻo ka hoʻoemi ʻana o ka puna wai lāʻau he zero, a ʻaʻohe ikaika kaomi ma ke apo ʻoki. Hiki ke ho'opa'a 'ia ka nut unfolding, a hiki ke ho'opa'a 'ia ke kino welded S tube no ka ho'iho'i 'ana i ka pa'i 'ana o ka puna wai. Hoʻopiʻi ʻia ka puna wai puna a uku ʻia ke āpau. Ma kēiaʻano, ua hōʻoia maikaʻiʻia ka hana silaʻana o ka pāʻani a me ke apo oki.

Huahana Huahana

Helu hapa: S020318003

Hoʻohana / Noʻonoʻo: ʻO ka pauma kaʻa

Nui: DN230

Nā hiʻohiʻona

1.30,000-60,000 m³ ola lawelawe, ka pā lole i hana mua ʻia

2.Duble-ring segmental alloy structure can effectively solve the problem of alloy collapse.

3.Over sized alloy width, maikaʻi hana sila, ʻoi aku ka pale ʻana i ka lole.

Ko makou Hale Waihona Puke